click pic to enlarge

One of the first things a process improvement specialist should realize is what kind of a problem are you dealing with when something goes wrong and it needs to be fixed as soon as possible.

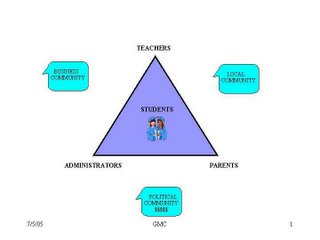

The above diagram is an example of three kinds of problem and how it would be approached in medical terms and business. Hopefully the business example will help make it more clear.

For example one, if by accident I cut off my arm please don't call in a problem solving team or try to figure out the root cause, stop the hemorrhaging, get it under control and then go back ASAP to determine the problem and solutions. More than likely special cause is at fault here and you don't have to change your system or process. Remove the special cause and prevent it from happening again.

Example two comes with experience, you have seen this type of problem over and over within your process or system. This type of problem is common (as in common cause) and it is inherent in your process/system. You will need to conduct a cost/benefit analysis as well as form a problem solving team (cross-functional if required). Remove as much variation as you can by implementing preventive measures. Remember, sometimes it may be too costly to remove all of the common causes/noise.

Example three is a deal breaker. Your process/system is out of control and you are throwing dollars and resources at it constantly. Improvement efforts are short term because you have no idea where the problems begin, meet or end. Wide variation is prevalent and your result measures tell you what you already know. This requires a specialized cross-functional team with solid leadership and subject matter experts from all interdependent departments. First identify and remove the special causes and work your way to a control situation and then reduce your common cause problems. If the process/system is too far gone and fixing it will still not bring customer satisfaction then it is time to design a new system/process using the correct resources and tools.