9/10/05

Whenever I get with a group of educators the discussions always include "

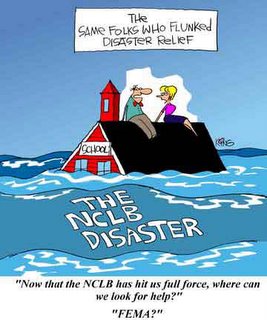

No Child Left Behind." The talks are usually lively with many thoughts and opinions flying around all at once. Perhaps that is part of the problem, everyone has an opinion and answer but no one has yet to find the solutions to our educational system.

I also recently received an email from an educator in Oregon who wanted to know if I believed in the No Child Left Behind Act (NCLB).

For those not familiar with NCLB,

For at least ten decades, American educators have failed to come up with the right and wrong way of teaching and learning. The best minds at all levels of academia have struggled with these questions.

NCLB was developed on the theory of "what's good for business is good for schools." School productivity would improve if business principles and applications were applied. If I remember correctly this is what was stated by then Texas governor George W. Bush and in Houston by Superintendent Rod Paige. If such improvements could happen in Texas, then they could happen everywhere in America.

There are many articles written on whether or not Texas indeed get better because of their standards. I do not have enough knowledge to agree or dispute those facts. However, the

Following are problems I have with NCLB based on my facts and data:

My first complaint is the fact is NCLB does not include grades K- thru grade 3, how can that be.? By not understanding the importance of building a solid foundation during this time tells me you have no idea about the importance of education.

Second, let's address "what's good for business is good for schools." What businesses were used as models? The ethics and values that ran

Enron (Hey, isn't Enron in Houston Texas, hope they did not use them as a model), Delphi, Adelphia, Arthur Anderson, WorldCom, Tyco, HealthSouth and others (see qualityg's write-up on --

CEO Fools that include examples of destructive leadership in action)? How about the mismanagement at

AT&T that destroyed an icon. What about the automakers and their suppliers who are going bankrupt because of there continued short-term focus on quarterly results. I know let's use our MBA Programs for how to do things right. Whoopsy, we have been doing that too and they are leading many of the before mentioned companies.

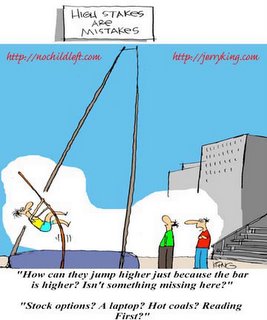

The last time I read over the act I was intrigued to find the Act stated "If a school fails to make test gains in two successive years, the school can be labeled a failing school and the school's administrators must write an extensive (100+pages) school improvement paper to justify their job and school."

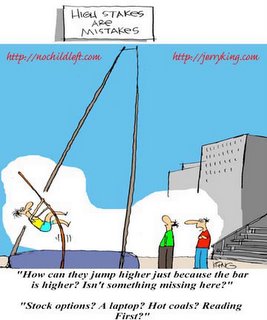

I'm not against school administrators writing improvement plans, but I question the validity of any test that only concentrates on a critical few (reading, math, science) and neglect the useful many (art, music, physical education, drama, play). Why does the plan have to be 100+ pages? Perhaps that is all that can fit on the white board (write - I will get better because I can, over and over).

How many schools are failing in your State? Do you know do you care? When I went to Michigan's Education site

Assessment & Accountability I found all sorts of assessments (MEAP, Education Yes, Merit Exams, Michigan School Report Card, MI-Access, National Assessment of Educational Progress and there are more). I could not find any schools that have failed the NCLB. If anyone knows of a school I would be very interested in reading their 100 + page report.

Double-spaced and in APA style format please!All I can find are programs that measure what we are doing wrong, but none that display the standardized procedures that should tell us what to do correctly.

I was wondering who does the assessing for all these programs? There must be an army of assessors invading the schools weekly. At what cost does the state tax payer's pay for all these programs. Who does the follow-up assessment?

In summary, I'm all for test and theory, but NCLB and other state programs have failed, time to move to the next one. Learn from the others and bring what was right forward and leave the rest behind. One more thing the Government need not apply to help!

Here is an added bonus for your review. Please go to MI Fed Educ Budget 2006. Is it just me or does the middle class continued to get hosed when it comes to Federal and State Aid?

To check your state go to State fact sheet fed budget 2006.

Updated 11/26/05

I was talking with some head Start Administrators last week and I was startled at the amount of paperwork they must do in order to keep funding for NCLB. What bothered me most was the fact that this lady has worked 18 years in Child Care and Head Start and will lose her job if she does not get her 4 year bachelor degree.

She is currently in college working towards her degree as she is closing in on 40 years old. Sraisingo is rasing two children that are still in school. I asked her if the college courses she was taking are helping her do the administrator paper work required by the Federal Government? "Absolutely Not!" The worst part is a young person graduating with a 4 year degree (practicum experience only) this year may be taking her job next year if she does get her degree finished on time.

qualityg says ... 18 years experience and being a mother is < (less than) a four year degree when it comes to handling children. Again, it's another example of people (Govt) trying to do good that have no idea on how to plan on doing good, just throw out a plan and see if it works, don't worry if children and child care workers get hurt. WHY CAN'T THERE BE SOME GRANDFATHER CONSIDERATIONS OR TESTING OUT FOR FOLKS WHO HAVE OVER 10 YEARS EXPERINECE IN THIS FIELD. C'mon get real here Secretary Spellings!

Did you know that the No Child Left Behind Act has a new roadmap for improvement for State Implementation?

A Road Map for State Implementation

Pre-publication copy

November 10, 2005

Please go this site to download a copy: http://www.ed.gov/admins/lead/account/roadmap/index.html?exp=2

qualityg will have more to say on this plan later. However, I want to know who said (from the plan) "What gets measured gets done" First of all that is not accurate, if you don't have a "plan" for measuring the right thing then you measure everything (I think the govt is good at that). Those who follow my Blog know I mention this phrase frequently and even posted my symbol that I have used since 1993. Geez, get it right!

Following is quoted from Page 2 of the letter from Secretary Spellings:

"NCLB is a law of principles. Since Secretary Margaret Spellings took the helm at the U.S. Department of Education (Department) earlier this year, she began describing the law’s “bright lines” – the essential and indispensable markers on the road to implementing

NCLB: Assessments in Grades 3-8: What gets measured is what gets done. States must test all students annually in reading and math in grades 3 through 8 and once in high school by the 2005-06 school year – not every other year or every other class, but all students every year."

Updated 12/12/05

No Child Left Behind: A Road Map for State Implementation (11/10/05)

I have been reviewing this document for a couple of weeks and I must confess I’m having a hard time following this roadmap. There are many “What’s,” but no “How’s.” A road map is supposed to provide some standardization so that no matter what type of map or tracking system if you put in the correct information you will get back a standard way to reach your destination.

The NCLB road map is a circle. You may think you are going to a better destination but I’m afraid you will end up right where you started with a lot more wear and tear and cost to your vehicle. Following are some initial thoughts and questions, more to come at a later date.

Sentences/paragraphs in

ITALICS are from the No Child Left Behind: A Road Map for State Implementation from Margaret Spellings – U.S. Secretary of Education. My questions and comments are in normal type.

The Road Map breaks down a sometimes-complex law into clear, common-sense principles, such as annual student assessment, disaggregation of data and proficiency by 2014. And it demonstrates the variety of fair and reliable methods being used to turn those principles into action. We want States to always be headed toward the right destination, even if how they get there differs along the way. From Cover Letter Page 1.

Ø Huh? common-sense? Ok we see the finish line, it doesn’t matter if you walk, crawl, run, take a train, or fly by balloon, just as long as you get to the same finish line (some just don’t make sense and some are just stupid). Efficiency and Effectiveness? By what method do you demonstrate fair and reliable? In order to do so you would need some success data, Please share so that we can see some hows and best practices?

The Road Map follows our announcement last spring of a New Path for No Child Left Behind. It was designed to reward States that showed real progress in reaching all students and improving academic achievement. We are pleased with the positive response they’ve shown. From Cover Letter Page 1.

Ø Does positive response = positive results?

Ø Who are they?

Disaggregated Data: Data are our best management tool. States and districts must provide data on student achievement by subgroup, inform parents in a timely manner about the quality of their child’s school, disseminate clear and understandable school and district report cards, and provide parents and the public with an accurate assessment of the quality of the teaching force. From Page 2.

Ø Please define timely manner?

Ø Good Data are your best management tool, is there a standard database for data on STUDENTS? I don’t think so.

Ø Accurate Assessment as opposed to what?

Highly -Qualified Teachers: States are responsible for implementing a rigorous system for ensuring teachers are highly qualified, making strong efforts to ensure that all students have access to highly qualified teachers, and providing support for recruiting and retaining the best and brightest teachers to our schools From Page 2.

Ø If state standards for teachers can be different how will I know that teachers in Mississippi are equal to those in Michigan? What happens if I move, does the NCLB provide teacher standards in a comparative form for each state? How could you, how could you know if there is wide variation and no standardization?

Results to date suggest this is a road worth traveling. Student achievement is improving in the United States, and student achievement gaps are closing. From Page 3.

Ø If states have different criteria and standards how can this statement be made? How can an individual state make this statement if they don’t collect data on individual students?

This document will help States and local educators understand what the Department expects as it reviews State policies and considers alternate policy options and flexibility for implementing specific requirements of NCLB. From Page 4.

Ø You mean it didn’t before?

Peer reviewers advise the Department on whether a State provides compelling evidence that its assessment system is consistent with NCLB requirements based on the totality of evidence submitted. Peer reviewers also provide constructive feedback to help States strengthen their assessment systems. From Page 5.

Ø What is a Peer Reviewer? Is there a list of names by State? How many are there? Seems very costly, is there associated training, what are their qualifications?

Refinement of Accountability/Adequate Yearly Progress (AYP) Measurement

There are a number of pages talking about sample populations, sub groups and sampling confidence Intervals. I always get nervous when I see everything being determined with average this and average that. I’m not a statistician so I would hope somewhere one would way in with their opinion in a common-sense manner for the general public.

Other States may want employ a statistical test to increase confidence in AYP determinations. In smaller States, or States with many small schools, such a test – a “confidence interval” – can help guard against making significant accountability decisions based on fluctuations in school performance or on the assessment results from a relatively small group of students.

There are other options as well. States may average student achievement data across grades and years to ensure more reliable AYP decisions. They may make different decisions about how to incorporate additional indicators into their AYP ratings. They may use “safe harbor” provisions or a growth index to factor improvements in student performance among the lowest performing students to make AYP determinations that are both valid and reliable. From Page - 8

Ø Safe Harbor??

Ø Average student achievement data – does that contradict that all students will improve. Won’t there still be some above and below average?

Ø Let’s suppose I have 5 students. There individual achieving are s follows (scale 1-100, 100 being the best). Student 1 – 80, Student 2 – 75, Student 3 – 75, Student 4 30, student 5 – 20. The average/mean would be 56. If I were to just show 56 it would convey an overall negative impression. How about adding the Mode – 75, and the Medium – 75. If I just looked at those individually it tells a different story, perhaps a more positive outlook for the same data. The range is 80 – 20, what does this tells us? What I’m trying to say is look at data from the Central Tendency. If you want a roadmap show all of the roads not just the ones where the average speed id 55 MPH.

Supplemental Educational Service Pilots

Supplemental educational services (SES) is an important component of NCLB, giving low-income parents real options to obtain free tutoring for their children. This extra help for students in schools in need of improvement, corrective action, and restructuring can be an important component of school improvement efforts.

Unfortunately, there is evidence from across the country that SES is not being implemented to its full potential. Too few eligible students are receiving SES. According to several studies, only 10 to 20 percent of eligible students across the country participated in SES during the 2003-04 school year. From Page 20.

Free Tutoring, this is an excellent concept for the “eligible” students. I know I had to take the initiative and hire a tutor for my kids at a rate of between 10-15 dollars an hour, 2-3 times a week. I did not have extra money laying around for this; it was just the right thing to do. All children should be eligible for tutoring. I know of at least 5 elementary and middle schools where this is offered. The eligible parents/guardians received numerous letters and handouts. The percent participating is far less than 10 –20 %. Some of the responses were – “I can’t get my kids to school any earlier”, or “I can’t keep my kids at school any later.” And, my favorite “They need the weekend to play.”

I will provide more questions later… until then, do your homework, don’t take my writings as gospel, it’s only information, gather your own facts and ask your own questions.

One final question --> Did anyone think of modeling all these ideas and improvement in a diverse set of school districts to be studied and then benchmarked. It would seem to me much more manageable, less costly and in the long run provide much needed standardization and timeliness of implemetation.

Other Posts on NCLB by qualityg:

NCLB is Scary

NCLB - The GAP Widens

UPDATED 8/9/06

ASPEN Institute Commission Hears about Impact of NCLB on Students with Disabilities

One of my frequent visits is to "The Aspen Institiute (http://www.aspeninstitute.org/)." The mission of the Aspen Institute is to foster enlightened leadership and open-minded dialogue. Through seminars, policy programs, conferences and leadership development initiatives, the Institute and its international partners seek to promote nonpartisan inquiry and an appreciation for timeless values.

I particularly like to read the "Commission On No Child Left Behind (Aspen - NCLB Commission)." Recently the Commission held a roundtable on the topic of "NCLB has increased attention and focus on achievement of students with disabilities."

The discussion centered on state assessments for students with disabilities and the impact of flexibility issued by the U.S. Department of Education on how schools are being held accountable for the achievement of these children.

The roundtable was co-chaired by Commissioners Judy Heumann and Ed Sontag. Commissioner Sontag stated, “Some have questioned whether children with disabilities can learn. NCLB has focused educators on increasing the performance of students with disabilities.”

qualityg says ... Commissioner Sontag there is the crux of your problem. Other issues stated in your report are the result of this stupidity. Concentrate on the Root Cause Upstream in this problem and the results will take care of themselves. Who are the "Some" referenced in your report.? Other possible solutions included the same ideas that every roundatble has on NCLB - more funding, more information, more funding, more highly qualified teachers, better curriculums and more funding. Every effort to move forward is curtailed by the "Some."

There were some excellent comments and recommendations:

Ricki Sabia, the Associate Director of the National Down Syndrome Society National Policy Center in Washington, DC stressed the need to debunk the myths about students with disabilities in order for NCLB to work at its fullest. She called for all students to be treated the same, to use a variety of assessments and sought to dispel the myth that students with disabilities cause schools to not make AYP.

Katy Beh Neas, Consortium for Citizens with Disabilities, Washington, DC credited NCLB with making schools focus on the academic achievement of students with disabilities. Along with her colleagues she strongly advocated to maintain students with disabilities as a subgroup within NCLB.

qualityg says ... Ladies I applaud your advocacy. However, one of the main "Somes" mentioned above are the very teachers everyone wants to train to become more "highly qualified" teachers. Many General Education teachers have a "Clandestine" war going on with NCLB and Special Education, it's best someone realizes this fact and bring it out at one of your roundtables.

For the complete report go to NCLB Disab Report

Another Site for excellent reports on education and some new ideas go to the Bill and Melinda Gates Foundation on Education at http://www.glf.org/Education/.

The USA Department of Education site for the NCLB Act can be found at http://www.ed.gov/nclb/landing.jhtml?src=pb

I check this site often, no new information has been listed for some time. Everything looks rosy if you read this site.

To read a post I wrote about Mainstreaming an Asperger Child go to

http://qualityg.blogspot.com/2006/07/quality-education-mainstreaming.html

update 8/25/06

The Commission of No Child Left Behind is releasing a Commission staff report on Growth Models: An examination within the context of NCLB. Since the enactment of the No Child Left Behind Act (NCLB) in early 2002, interest and discussion over tracking growth in achievement, or using growth models, has increased tremendously. The Commission staff analyzed necessary data components as well as an examined the benefits and disadvantages of incorporating and utilizing a growth model within NCLB. Lastly, the paper includes a brief discussion of two growth model pilot programs recently approved by the U.S. Department of Education in Tennessee and North Carolina.

Michigan School Report Card shows failing grades - 88.5% in 2006, down from 88.1% in 2005

The execuses for failure amaze me, it's alaways something or someone else who is to blame instead of personal accountability. For example Detroit Superintendent William F Coleman III said the reason Detroit fared worse this year (103 schools failed) than last (63 failed) is because the state moved up the testing period for the MEAP test to October from February (less time for teachers to prepare).

qualityg asks ... Then how come a large amount of those schools that failed are repeat offenders that go back at least 5 years of failure?

qualityg says ... And the teachers are going out on strike?

qualityg asks ... How come the "quality" of the Administration Personnel" are not included in calculation? Teacher quality is evaluated, why not their support system and bosses? Management (bosses) owns the system and they should be accountable.

Go to www.michigan.gov/mde for complete report.

Another Post (9/10/06) by qualityg at : http://qualityg.blogspot.com/2006/09/quality-education-nclb-is-close-to.html

I started to wonder how many parents actually knew the person teaching their child is only a few years older than their child and may or may not have as much application in the field that they are instructing.

I started to wonder how many parents actually knew the person teaching their child is only a few years older than their child and may or may not have as much application in the field that they are instructing.