"What Gets Planned and Measured Gets Done" Comments on the state of affairs in business, organizations, academics, process improvement, quality, education, government, etc...

Wednesday, February 28, 2007

Detroit Car Makers Continue Their Downward Spiral - Part II

Part II

The National and Local Media have a new story about the fate of the Detroit Auto Industry. Quotes and interviews from the Executive Leaders, and employees are bountiful. Notice I did not mention Union Officials who are lying low under some rock until the worse is over and them come out kicking and screaming. The problem is they have a million less members that they did 25 years ago.

Each has their own views and each does not talk much about “Customers” or plans to gain and understand their customer base and what it takes to gain customer satisfaction.

For example read the following to-do-list from Ford’s executive vice president Mark Fields:

It's formidable:

Finish idling

seven assembly plants.

Identify two more assembly and five more parts plants for closure.

Execute 38,000 hourly buyouts.

Complete salaried separation program eliminating 10,000 jobs.

Determine if involuntary layoffs are necessary.

Launch new products this year without quality problems.

Replace Ford, Mercury and Lincoln lineup by 2010.

Get workers remaining to believe Ford has the products, team and plan to win.

C’mon, no mention of the customer, degrading comments about there so-called number one asset à Employees and we all know the lost of experience you will have so how can you make a statement about launching new products without quality problems. I have heard that one for the past 20 years. I don’t mean to pick solely on Mr. Fields because the other Leaders (GM & Chrysler) do it too, it’s just Mr. Fields is the most recent (2/24/07).

What about Price? The auto companies and other major corporations that continue to layoff employees can’t seem to understand they are cutting there own throats when it comes to customer base. Sure many get new jobs but at what salary?

The papers are full of articles about the new hip designs and marketers that are now designing cars for women and the 18 – 34 year old customer base and so on but can they afford the price of these lavish new cars that offer sleek design, vibrant colors and extended warranty packages that leave little to be desired.

The Koreans and Chinese will continue to gain market share percent by percent because they offer a price that a good majority (working poor) of potential customers can afford with some hefty warranties. I wonder how many customers are included in the following Poverty statistics from the U.S. Census Bureau:

Deepest poverty

States with most people living in severe poverty (and the state's rank in population):

California -- 1.9 million (1)

Texas -- 1.6 million (2)

New York -- 1.2 million (3)

Florida -- 943,670 (4)

Illinois -- 681,786 (5)

Ohio -- 657,415 (7)

Pennsylvania -- 618,229 (6)

Michigan -- 576,428 (8)

Georgia -- 562,014 (9)

North Carolina -- 523,511 (11)

qualityg says ... One more thing when will you (GM, Ford & Chrysler) end the ridiculous advertising bait and hook tactics about a reduced price that is only available for employees. The print is small and the TV announcer mentions it quickly but nothing makes a customer madder than to be told once they enter the dealership that the price they saw on TV or in the paper is for employees only. Besides how many employees do you have left? Will the employees left behind spend the money when they are waiting for the hammer to fall on them? How stupid is your Marketing department anyway.

Saturday, February 24, 2007

Detroit Car Makers Continue Their Downward Spiral - Part I

Ford Motor Co., continues firing employees and immediately escorting them from corporate buildings at the same time refusing others who want the buyout but work in areas where if all the employees left they would be in trouble.

Another move is to hire a new Executive Vice President who comes in and does the slashing because those leaders who have been with the company for a long time don't have the stomach for mass execution of their employees and workers. Then you have the short-term executives (5 years and less) who make short-term decisions over the years with their own careers as the focal point and not the company. What makes it worse many of them have "Platinum Parachutes" that will reward them for their slashing.

qg says... This is not a new tactic, it's an old "punk" tactic that treats employees like cattle with mad cow disease.

The first time I saw this tactic was at my company (also Detroit Michigan) I used to work for in 1988. One of my co-workers was breaking down at her desk as a HR person and a security guard stood over holding boxes for her to pack personal goods. Her "sissy" boss wouldn't even come by and say good bye. When I walked over to say a few words and help her back I was told by the security guard to stand back and go back to my desk.

Others had now gathered, I basically said " Buddy, I don't think you want to stand here and tell me that when you only make $6.25 an hour that I can't help my friend. Over the years tactics got worse, calling people into a fake meeting and telling them they lost their jobs. Human Resource Managers and security guards walking into the cafeteria and walking people out the door and told them their personal belongings will be sent to them (we called it "Tapping").

Executives from outside the industry were hired (create a new lean culture) to come in and install a new "Me Competitive Culture" that says look out for number 1 and the hell with the company. They did a good job of pitting Department against Department and co-workers against co-workers who would do anything to save their own jobs.

The Executives who did the dirty work left within 2-3 years doing the job they were hired to do with bonuses and a trail of bodies that was added to for years and years until this day.

All during this time the Company will put out public and inter office announcements telling everyone how difficult this is and they are doing it in the best manner possible. You see the mentality is to get the wounded and dying out of the way quickly before the remaining troops see them and get further depressed.

If you don't see a face it's hard to get emotional, besides those that remain now have double and triple the amount of work because company managers did a dismal job of matching the amount of people needed with the number given to be cut by the Financial Pirates.

Check out some of the more recent comments from Ford Executives (some have just been hired and put in positions of deciding how many employees must go):

As Ford Motor Co. works through thousands of employee buyouts, Executive Vice President Mark Fields sent a memo Thursday advising managers to handle the process with decency and humanity.

Some employees who wanted to leave Ford said their managers told them they no longer could take a buyout and, if they stayed, they could be demoted, relocated or have to take a pay cut. Some said Ford was trying to get them to quit without taking an expensive package.

In addition he said "As a supervisor, it is especially important to be accessible and supportive of your team during the transition. Most importantly, make sure your employees know what is expected of them and help them deliver on their objectives."

"People are furious," a Ford Manager said. "Do you hear me? Furious, with a capital 'F.' Crying. ... They may have to relocate, and they may have to take a lower-paying job. It's just horrible the way people are being treated."

One employee who anticipated the buyout and was told time and time again to find a new job and take the offer sold his house, accepted a new job in another state and then later was told he could not go because he and his boss now had to run the Department. Did I mention his wife also quit her job.

And finally Executive Vice President Mark Fields says (I'm sure from his own personal experiences):

- "While these actions are difficult, they are necessary ... to create the foundation for future profitable growth.

- "We recognize it's hard to say good-bye to friends and colleagues -- their contributions and years of service are greatly appreciated."

- "Employees who accepted a conditional voluntary separation offer will be individually notified by their manager, no later than Feb. 27, as to whether their offer can be granted.

- "This change will introduce a period of transition -- the process by which we must leave behind old ways of doing things and develop creative and effective ways to work with a third fewer people."

General Motors

Chrysler

Speculation of a Chrysler Group sale was sparked last week when DaimlerChrysler Chairman Dieter Zetsche said all options were being considered for the Auburn Hills unit. The news came as DaimlerChrysler announced a restructuring plan that calls for cutting 13,000 jobs in Chrysler Group.

With 13,000 job cuts and a sale of the division being explored, Chrysler Group CEO Tom LaSorda (he is new too) is trying to calm the nerves of employees and dealers with e-mails and conference calls.

In an e-mail sent late Wednesday, LaSorda (not the ex-LA Dodger Manager) told Chrysler employees that terms of the buyout and early-retirement packages could be ready "in the next few days." I think Tommy LaSorda from the Dodgers should be hired next.

Saturday, February 10, 2007

Misc --> "Q & A" Email Chute on Quality- "All Hail King LEAR "Ichan" see (Q16)

Occasionally I get Emails sent to me rather than posting them on my blogsite. Most of them are people expressing their views on education, quality and leadrship. Some are Misc type general questions that I will post under “qualityg’s Email Chute.” Thanks to all that Email and post comments.

One of the satisfactions of writing this blog is the interesting Emails I receive and the correspondence I have developed since April 2005.

The questions and comments are as diverse as the subject matter (Quality & Process Improvement, Education, CEOs, etc) that I post about in my blog.

95% of my responses do not get put into this section. Most of my responses can be long and I attach as many documents and information that I can to help the requestor.

7/27/05

Q1) “What do you think is the most important process in a company?

- Jackie B.

A1) Years ago I gave the standard quality response “ the most important process that any company has is the process (es) that adds value to the customer.” About ten years ago I changed my answer and still believe the “hiring” process is the most important process in the company. Many people have debated me on that answer and there is truth to there arguments. So if it’s not the most important I say it is the most important “undervalued” process in a company.

We all know most American Management spout employees are the most important assets to a company. Then why are they considered an expense that needs to be reduced to make up for debt or loss of revenue (because it’s easy)? Human Resources don’t carry much weight when it comes to being considered a critical department within an organization. However, when you stop looking through narrow eyes and open your self to systems thinking (end-to-end), the HR department is at the beginning and the end of an employees process. HR hires and HR conducts your exit review and papers.

Now, think in terms of process control and understand that most problems occur early on in a process and they intern cause multiple downstream problems and bottlenecks. Quality Experts and Process Improvement Teams will attack and try to correct all the “symptoms” downstream (often blaming a person and not the system). The process originated by placing employees in jobs they are not qualified for or can no longer do the job as technology increases and more skills are required (just a few examples). Maybe the HR representatives are not qualified or have the tools to do their jobs.

You see Jackie, Management owns the hiring system. It is not a worker’s fault if placed in a job where failure is guaranteed. It is not the worker’s fault if a company slashes training and education that is required as new technology is implemented. It is Management’s job to replace the worker if they are not performing and place them in a job where they can take pride of their work (do we really think people want to fail).

Q2) “I'm new to blogging and visit a lot of sites (personal blogs) that discuss Quality, Business and provide ideas for Process Improvements. Most of them have ads on the side that have a number of businesses spouting the same subjects, why does your site not endorse these advertisements?

– Joyce O.

A2) High-level explanation - most of the ads you see are generated from Google and Yahoo. They both (others too) have programs that will pay the site owner (owner contacts them to allow on site) each time the ad is accessed by a visitor. A count is kept and you receive money from Google or Yahoo.

My decision not to run the ads is strictly my own and I find no fault for others that do run the ads. I “often” post disagreements with many of the so-called quality and process consultants trying to get business through the web. I feel I would be hypercritical to my beliefs about what I question (quality, education, government) and to the purpose of my site. After all, if it’s on my site that would give you the reader, the perception that I endorse them.

I do promote books and other items within many of my posts that I feel are interesting and may prove beneficial to those that visit my site.

8/2/05

Q3) In many of your posts you blast management for not doing there jobs, when an employee screws up on the job why do you say it's managements fault?

- Janice S.

A3) I'm going to assume you are in management. If you don't know, or can't understand from reading my posts, I can't help you.

8/16/05

Q4) You appear to be an advocate of the customer, I am a member of a quality team where I work. The only help we get from management is “reduce the number of customer complaints.” How important is it to use their complaints as opportunities for process improvement?

- Brenda from Houston

A4) That is not an unusual request from management and it usually comes down from an emotional reaction from a higher up who hears from one of his/her peers or it becomes common knowledge in the press.

If you can quantify the amount of complaints or better yet have some trending data that has been continuously tracked then use the data (if it’s reliable). Does the data show the process is out of control (one time event), or is it normal variation at work? How do you know? This should determined before dissecting and tearing up a process for no good reason.

If no hard data, then you have a much tougher road ahead if that is required by management (if you plan on doing a survey or setting up measurements make sure you use an expert to help you set up the plan).

When using customer data I prefer to use “customer input” as opposed to customer complaints. That means as part of your recommendation you need to convince management that if customer input was done in the “design stage” and as part of an on-going process measure the chances of working on this type of problem after the fact is greatly reduced.

Q5) I would like your opinion about what was said at a staff meeting I attended last week. The Six Sigma Black Belt and our Manager kept stressing that Quality is everybody’s job and we are all responsible. What would Qualityg say?

- Aaron A

A5) AA, qualityg says… Quality folks (including some consultants) and managers who commit to helping and delegating responsibility down often use that bogus cliché, and I call it the “Pontius Pilate Effect.” That means they (especially mid and upper managers) wash their hands of the whole thing and walk away and stay on the sidelines. A big contributing factor in the demise of American Management. Plain and simple it's management's job.

On face value (of course we all want to do a quality job) it seems like a great statement, the problem is when everyone is responsible, no one is responsible. Think of the old quality control mentality (unfortunately it still exists), when a person believes the next person in line/process is responsible for quality they feel they can let it go through because it didn’t happen in my shop and somebody down stream will catch it a fix it.

9/3/05

Q6) Gas prices are going up, up, up. I'm in Finance (I don't think you like us) how should Management address this issue since it's one of those costs that was not budgeted for at this price. - Brett from Dearborn

A6) We live in the same backyard. It's not that I don't like Finance folks, it's just I hate it when Finance tries to be bigger than the whole company. It takes all parts moving in the same location for the common good. Many Finance Leaders manage with blinders.

As for Gas prices, I learned today that Michigan has the highest gas prices in the nation (we also have the highest unemployment). I am not a big fan of Telecommuting or working from home on a regular basis. However, in these times Leaders should allow those folks who can do work from home do it for the time being until gas prices get in control. What better way to stop the oil lords from making hefty profits than to stop buying gas? Even 2-3 days per week would help.

9/14/05

Q7) At a school meeting this week the subject of dropouts came up and one teacher suggested providing incentives to keep the kids in school. What is your opinion qualityg?

- Red Sox Fan

A7) Now that I am studying, researching, testing, observing and assessing “Early Childhood” behavior I am more convinced that teachers, parents, coaches and to some extent peers drive out the intrinsic motivation that each child has when starting school as early as the Pre-K level (not a new discovery by any means, but it helps me understand the end-to-end education system from an application view and not just theory).

We are taking from our children the chance to experience “Joy of Learning” (Deming). These types of suggestions are alarming to me because the education system is following the same pattern as big business. Incentives, rewards, etc... are extrinsic motivators that drive the wrong behavior.

updated 9/15/05 - If students come to view learning as a means to get a reward/incentive, they will not longer identify learning as something worth doing for the long-term (whole life). American Management still believes rewards and incentives are the way to motivate employees to do a better job. At best, rewards will get some temporary reaction, but it does not last, nor does it change behaviors for the long term and it does more harm than good. Same thing will happen in education. PLEASE DO NOT LET THIS HAPPEN!!

People are not realizing that fear, incentives (you can have candy if your good or if you eat your vegetables you can have a big piece of cake) negativity, threats, rating students, ranking students are extrinsic in nature and it is these same motivators (negative) used at an early age that drove the inclination to learn out in the first place.

By most accounts (see Detroit Free Press - Failed High Schools) studies have shown there is a 30 – 35% dropout rate at the high school level. The Alliance for Excellent Education research shows that between 80 –85% of Americans believe the number one priority in our country is high school education.

WRONG!!! Here we go again not looking at the systemic nature (end-to-end) of the problem. High School is the output. 95% percent of most problems can be found in the planning, design and the first few input steps of any process. Please start to understand the cost and tampering you are continually doing to this system.

By suggesting High School is where we should put the majority of money and effort is like bringing back quality control at the end of the production line.

Systems Optimization: It’s about interdependencies, we must realize that change cannot occur in one school level without affecting the performance and outcome in all other parts of the primary educational system, the system as a whole, and ultimately all other systems by which the school system operates.

updated 9/27/05

Q8) I am perplexed, about a month or so ago our CEO gave a speech rallying the troops stating “that we need to be more creative because we are going to focus more on being a Global force.” My company supplies the auto company and we focus on putting together complete automotive interiors, including seat systems, interior trim and electrical systems. While visiting our office he made a comment wanting to know why he saw so many “foreign” cars in the company parking lot.- Dumbfounded in Detroit

A8) DID, your CEO sounds like a candidate for qualityg’s section on FOOLS. Since this type of tragedy happens in may companies let me answer if this was like a Shakespearian tragedy like “King Lear.” It’s generally regarded as one of William Shakespeare’s greatest tragedies. I may be making a stretch here in stating that the “Global” speech was made at your headquarters or somewhere the CEO wanted to get some print because after all the CEO is like a “Caesar.” Since you are from Dearborn I would bet that your CEO (Caesar) did what any kiss-up emperor would do, and that is, Detroit is the home of what was the "Big 3" I’m sure he is playing his act for the US automakers. Alas, behind every Caesar is a Brutus and eventually those who play both sides of the fence will eventually be caught. I just hope the employees will not suffer because that would be the greatest tragedy of all!! If you drive a foreign car and it has a component from your company just tell the CEO you’re advertising the company's product. If not, ask him why your Senate Management Team (they own the system) has not truly entered the global marketplace.

A8) DID, your CEO sounds like a candidate for qualityg’s section on FOOLS. Since this type of tragedy happens in may companies let me answer if this was like a Shakespearian tragedy like “King Lear.” It’s generally regarded as one of William Shakespeare’s greatest tragedies. I may be making a stretch here in stating that the “Global” speech was made at your headquarters or somewhere the CEO wanted to get some print because after all the CEO is like a “Caesar.” Since you are from Dearborn I would bet that your CEO (Caesar) did what any kiss-up emperor would do, and that is, Detroit is the home of what was the "Big 3" I’m sure he is playing his act for the US automakers. Alas, behind every Caesar is a Brutus and eventually those who play both sides of the fence will eventually be caught. I just hope the employees will not suffer because that would be the greatest tragedy of all!! If you drive a foreign car and it has a component from your company just tell the CEO you’re advertising the company's product. If not, ask him why your Senate Management Team (they own the system) has not truly entered the global marketplace.Q9) While reading through your post Leadership, Knowledge, People I laughed out loud when I read

"I’m tired of Financial bean counters/MBA pontificators who want to drain organizations of innovation, creativity and passion. Condense it all to the bottom line, in the box, or better yet, “paint by the numbers and don’t go outside the lines.” Boundaries cause employees to stop working, and worse yet, worry about what each other is doing as opposed to concentrating on what matters most to the customer! "

What made you write such a statement? - Reggie

A9) I wrote that in the mid 90's after attending monthly planning meeting after monthly planning meeting when many of the executives wanted to know only about bottom line results. The second person always to speak after the leader was someone from Finance. He/she would bring binders of data and information. There never was analysis being done, just make sure these numbers change next week. Didn't care about Why, only about Whom.

In my line of business at the time there was not much creativity or innovation being transformed into products that would lead to increased sales and revenue. Our customers were waiting for the next big doodad (it came if the form of Wireless Phones).

It's much like today with auto incentives; consumers are waiting for the next expected deal from the car manufacturers. Those incentives that were used earlier in the year are now expected and no longer motivate the buyer, they want new and they want now or they will wait.

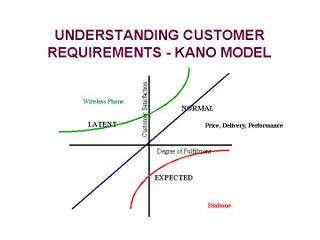

Perhaps the following Kano Model will help, click to enlarge:

Expected Requirements - are those that are so obvious to the customer that they do not state expectations clearly. When these expectations are met, the customer says nothing, and probably doesn't even notice. When these features or services are not present, the customer complains. Continually improving on meeting these kinds of needs will not entice customer loyalty or delight.

Example: Telephone dialtone. If it is slow in coming or missing, customers are not happy. When it is present, the customer does not notice, much less become loyal to the provider.

Normal Requirements - Sometimes referred to as "basic" quality. Customers are attracted to these needs and are quite aware of them. When these needs are met, customers are satisfied, when they are not met customers are dissatisfied. For many types of requirements in this category, it is possible to deliver more than customer requirements and create additional benefit/revenue.

Example: Price, Performance, Delivery.

Latent Needs - These are often referred to, as “WOW” needs. They are real, but not yet in the customers' perception. If a company does not meet these needs, there is no customer reaction. They are not dissatisfied, because the need is hidden to them. If a company understands such a need and fulfills it, the customer is delighted. It delights and excites customers and creates customer loyalty. Once these needs are obtained they then become Expected or Normal in the wants and needs of the customer.

Example: Cell Phones, Auto Incentives

Needless to say, if a company is only interested in the bottom line they will never realize a sustained flow of "Latent" needs that are required for growth.

A Latent need for a Finance person is finding a quarter in the men's room at the airport. A MBA pontificator will find the same quarter and use it for the stall door. Me, I tell the person I'm with hey there is a quarter on the floor, shucks; I don't have one can you put it in the slot for me?

Q10) Every year around this time my company cancels “Training” for the rest of the year saying we are over budget and must cut back on expenses. Any ideas on how we can show that Training is value added?

- Shelly from Sooner Country

A10) Wow, you made it this long without being cut. No pun intended, its just I’ve seen Training budgets slashed as early as April. I have always believed Training should be an Asset and not an expense on the financial sheets. The problem was how do we show value to be considered an asset.

I spent a number of years in Training years ago and it was always a struggle to show value because it was difficult to measure value-added measures because once training was done we had no way to know if the training was successful. Sure we had the rational after training surveys (i.e., class, instructors, setting, etc), but we did not have the resources or dollars to extend surveys after every training class.

What we did do was set up some process and quality training measures and began to measure them for the most critical and costly training programs. The following process flow may help.

PLEASE CLICK ON PICTURE ONCE, WHEN IT COMES UP, CLICK AGAIN on 4 square arrows FOR LARGER PICTURE (send me an email if you need a better copy - qualityg@comcast.net)

12/28/05

Q11) – I recently received an interesting Email. He said:

“I have been assigned to find a company that specializes in Continuous Process Improvement (Kaizen). There are thousands of hits off the Search Engines. I was intrigued by your blog because you don’t advertise all those silly ads and you seem to say (question) it straight as opposed to implying you are an expert. Can you “please” recommend a company I can contact?

- Desperate in Atlanta

click on picture to enlarge

A11) Before and after the Internet explosion I had the responsibility of traveling the United States attending many Quality Forums, Seminars, Trainings, etc by Quality professionals all promising one way or another that their product and services was the answer to my company’s needs and requirements.

I found some promising (we eventually settled on one now bought out by another vendor which I do not support) but most were nothing more than charlatans hiding behind some buzz words and articles that others had written in the American Society for Control (now ASQ) Magazine.

The Internet has increased the number of Charlatans advertising by 10 fold and now blogs have added another ten fold of Houdini quality wannabees. Personally as I stated before I don’t care if folks advertise on their sites but it is strange they would promote someone else selling the same stuff they are trying to sell (that should be your first warming) on their blogs.

Don’t let any Internet site convince you they have the solutions or answers to your problems (second warning). Watch out for ones that criticize others with no basis or facts other than what they think they know (third warning). Remember, the Internet is information, not knowledge. I call it the “Global Billboard.”

Do your homework, create a list of questions, visit the company or request they visit you, agree to nothing over the phone or any form of E-mail or Web communicating other than getting information. Continue to ask questions and more questions that pertain to your situation, if you get wide variation of answers from Manufacturing to Service to … that they do it all hang up immediately (fourth warning). If you become more interested ask foe a list of clients and contacts, DO NOT let them send you to one or to recommend whom to call. If they will not do this, say good bye (fifth warning). If the company does not have enough resources to handle a company of your size, sayonara (sixth warning). Ask for a history of the company you want to do business with, how many times have they changed their names to join on the quality band wagon (Q – Circles to Lean Sigma, seventh warning) Last warning, if the company you are dealing with does not have employees trained by one of the Masters or one of their “appointed” followers keep searching. Just make sure they are not self proclaiming themselves.

You would be amazed by the answers or no answers I get to questions from Blog sites that proclaim self-imposed expertise. I am no expert, just one person seeking Profound Knowledge by asking continual questions that has traveled the Q shaped road for many years.. I hope the couple of leads I sent will help. Good Luck

p/s – I entered “Quality Consultants” in the Yahoo Search Engine. I stopped after 30 pages. If all these consultants have all the answers and can train your people better why are we such in bad shape?

1/1/06

Q12) QualityG could you provide feedback on my article about the Deming Wheel and did you attend his seminars while he was alive?

Regards - http://www.demingindia.org/

A12) From what I have read and experienced in my studies and application of Dr. Deming’s teachings since 1980 I believe you did a thorough study of explaining the evolution of the Deming Wheel.

For the reasons you stated I started referring to the PDCA wheel as the PDSA cycle in the mid 1980s. It became apparent to me while working with quality teams the Check stage was being done as a “quick” glance to determine if the process was performing as expected. I explained to them the difference between check and study was as great as the difference between Lightening” and Lightening Bug.”

I equate the Study stage to understanding “Variation.” By studying the process we determine if the improvement or change that was Planned and Done produced the predicted outcome. If one does not understand Variation then how will one know what to Act upon in the final stage?

As you stated how will we know if our commitment (specification), effort (production) and act (inspection) without doing a thorough study.

The PDSA Cycle in my opinion is the foundation for all of the process improvement programs (TQM, ISO, Reengineering, Lean, Six Sigma, etc) that evolved since the 1980s.

I can testify to the fact about Dr. Deming’s 4-day seminars. Having attended three of them they were different, but in a good way since continual knowledge was always prevalent from one seminar to the next.

Your explanation and examples of theory are excellent. I use Data + Information + Application (theory) = Knowledge, Knowledge + Listening+ Observing = Wisdom. (D+I+A=K)

(K+L+O=W).

The steps you identified in understanding the ‘Theory of Knowledge” are very good. I would only add Theory of Knowledge provides the “ability for management to predict.”

Based on Dr. Deming and Dr Russell Ackoff’s teachings I have become a “Systems Thinker.” By this I mean every process must be looked at from a ‘Holistic” viewpoint in order to optimize the system as a whole.

Profound Knowledge in my “humble” opinion is the ultimate example of how each part is interrelated and inseparable just like the PDSA Cycle.

By no means am I an expert or an authority on Dr. Deming, I just keep applying and verifying in order to continue to learn. I know there are many more authorities and scholars of his work, I’m just one of his “willing humble students.”

I’m attaching a handout (click to enlarge) I put together years ago explaining Dr. Deming’s “Quality Chain.”

Q13) I have received a number of posts about providing information on Pareto Analysis and Data Collection.

A13) I hope the following blogs help answer those requests. Go to the following for more information and examples:

Pareto Analysis - http://qualityg.blogspot.com/2006/07/quality-tooltechnique-pareto-chart.html

Data Collection - data collection + forms

4/5/06

Q14) Would you share what you believe to be some Quality Leader Characteristics?

Regards - Raj

A14) - I can only share what I aspired, desired and inspired to be:

CLICK TO ENLARGE MODEL:

Q15) What does Dilbert (and qualityg) Think of Six Sigma?

A15) Click on Pick to Enlarge

2/10/07

I received an Email from an old friend this morning after he read the morning newspaper. Before answering this question I would like to re-post a question and my answer I received from a reader in 2005 (Q8) that is about the same company and CEO in question for Q16) . The sender of Q8 asked that I not mention the Company name (he no longer works for Lear, he was laid off). qg

Q16) qg, I know you must have some thoughts about the latest CEO and Senior Leadership Debacle at Lear Corporation?

Q8) I am perplexed, about a month or so ago our CEO gave a speech rallying the troops stating “that we need to be more creative because we are going to focus more on being a Global force.” My company supplies the auto company and we focus on putting together complete automotive interiors, including seat systems, interior trim and electrical systems. While visiting our office he made a comment wanting to know why he saw so many “foreign” cars in the company parking lot.- Dumbfounded in Detroit

A8) DID, your CEO sounds like a candidate for qualityg’s section on FOOLS. Since this type of tragedy happens in may companies let me answer if this was like a Shakespearian tragedy like “King Lear.” It’s generally regarded as one of William Shakespeare’s greatest tragedies. I may be making a stretch here in stating that the “Global” speech was made at your headquarters or somewhere the CEO wanted to get some print because after all the CEO is like a “Caesar.” Since you are from Dearborn I would bet that your CEO (Caesar) did what any kiss-up emperor would do, and that is, Detroit is the home of what was the "Big 3" I’m sure he is playing his act for the US automakers. Alas, behind every Caesar is a Brutus and eventually those who play both sides of the fence will eventually be caught. I just hope the employees will not suffer because that would be the greatest tragedy of all!! If you drive a foreign car and it has a component from your company just tell the CEO you’re advertising the company's product. If not, ask him why your Senate Management Team (they own the system) has not truly entered the global marketplace.

A8) DID, your CEO sounds like a candidate for qualityg’s section on FOOLS. Since this type of tragedy happens in may companies let me answer if this was like a Shakespearian tragedy like “King Lear.” It’s generally regarded as one of William Shakespeare’s greatest tragedies. I may be making a stretch here in stating that the “Global” speech was made at your headquarters or somewhere the CEO wanted to get some print because after all the CEO is like a “Caesar.” Since you are from Dearborn I would bet that your CEO (Caesar) did what any kiss-up emperor would do, and that is, Detroit is the home of what was the "Big 3" I’m sure he is playing his act for the US automakers. Alas, behind every Caesar is a Brutus and eventually those who play both sides of the fence will eventually be caught. I just hope the employees will not suffer because that would be the greatest tragedy of all!! If you drive a foreign car and it has a component from your company just tell the CEO you’re advertising the company's product. If not, ask him why your Senate Management Team (they own the system) has not truly entered the global marketplace.

A16) Old friend, wouldn’t it be wonderful to have a billion dollars like Carl Icahn and just play monopoly all day against another billionaire named Kirk Kerkorian (are these guys related)?

These two guys who made mucho money with takeovers and gambling should be the poster boys for how NOT to create company loyalty by anyone under the Senior Leadership Team.

Mr. Icahn is offering the CEO in my post above Robert Rossiter would get $20.3 million dollars to stay and millions more in stock in the proposed takeover. There are some other Lear Executives who will also get many millions too. Can someone tell me about the rest of the employees? Oh yeah, be lucky you have a job, for now.

Whoops forgot to mention Lear lost more than 2 BILLION dollars in the past few years. I wish I worked that that fine place of employment. I would be so geeked to want to follow the current leadership team while they get millions and the company loses billions. Geez I thought I heard some President last week talking about the outrageous salaries that are given to CEOs. Time to Step up Mr. Bush.

The only consolations I take are the companies I invest in are also led by Billionaires (Mr.Buffett and Mr. Gates) who act accordingly and like true Leaders.

Thursday, February 01, 2007

PROCESS/QUALITY MEASURES FOR THE “SALES FUNNEL PROCESS AND ORDER FLOW”

Sales in particular are different. Sales main goal or measurement is usually how much revenue they generate within a stated time period (i.e. monthly or quarterly). Some companies now include profitability and customer satisfaction with the sales process, but these measures are not always the most effective for the sales process.

So the first step in establishing sales measures is identifying all of your customers and then to begin to define their requirements. These requirements will begin to identify both Process Input (efficiency) and Quality Output Measures (effectiveness). For example, external customers (envision yourself as one) may measure salespeople on how quickly they respond to requests for information, how well the response meets their information requirements, or how well the salesperson understands his or her product or service. Customers also will perceive or evaluate the salesperson on how well the solution performs after it is delivered. In other words, did the product or service that the salesperson recommends meet the customer’s requirements?

One of the pitfalls that many companies fall into in gathering this type of information is having a middle person or outside agency (i.e. distributor, telemarketer) gathers this information and not truly understanding the requirements of the customer. Where I worked we contracted a distributor to sell some of our services. When sales were lower than forecasted we asked the distributor to survey customers as to why they did not buy the service, the distributor informed us that the price was too high.

Think of the sales funnel like a plant conveyor belt, sales leads and information pass through the funnel (Process Measures P1 – P5) just like raw materials are passed on a conveyor belt. The Quality Output (Q1) of this process is a timely, accurate and complete order (closed) that meets customer requirements.

Measuring the sales process at each step can help sales managers predict (sole purpose of process measures) upcoming problems so they can take corrective/preventive actions. When preventive or corrective actions are required it is best to implement them as far upstream in the process as possible. For example, two key in-process measures that many companies have found useful is the average time it takes to get a lead through each step in the funnel process and the conversion rate that is associated with the leads. The conversion rate is the ratio of prospective customers or orders that move forward through each step of the sales process.

It is my belief that one of the most important qualities a manager can have is the ability to predict. In order to that a manager must be able to acquire the knowledge to base his/her decision on facts (ie; historical/ trend data) from an end-end perspective.

By measuring each step of the sales process (funnel) a Sales Manager can predict the number of leads that their sales people need to achieve their sales quota. The number of leads going into the funnel is a leading indicator of sales performance. While much of this is common knowledge to most Sales Teams, the one fault many make is to wait until the end of the month to take action. Historical data can also provide a means for prediction. For example, if we were to look back and calculate how many leads have turned into sales we can assume the future ratio will be the same unless improvement activities are put in place to change the process. Because we know every lead does not become a customer, another way to look at improving the process is to reject quickly those leads that are not likely to become a sell for a product or service.

Think of these leads like a defect. Just like in any process the objective is to remove the non-value added items as soon as possible so that the cycle time of the overall process is streamlined.

Aligning sales measures with the overall corporate objectives is a key factor. Salespeople are the lifeblood of a corporation and their input is required for many process improvement activities. Many companies today are also measuring salespeople on customer satisfaction. When I purchased my new van last year it wasn’t a week later that I received a survey in the mail requesting that I inform them on how well the salesperson performed. However, customer satisfaction scores based on small sample sizes can be misleading, caution should be taken if the salesperson does not have a high volume of customer transactions.

Implementation of any new process control system should be piloted in a few areas before wide spread rollout.

A useful tool to monitor and measure a salesperson’s in-process performance is by creating a “Sales Funnel Accomplishment Plan.”

Click on Pic To Enlarge

Additional measures to consider monitoring include:

Customer - measures from the customer’s perspective.

1) Did the product/service meet the customer’s requirements

2) Was the salesperson knowledgeable

3) Was the salesperson responsive

4) Retention Rate

5) New Sales vs Disconnects

Financial - traditional measures

1) Sales dollar volume

2) Profit by order

3) Profit by customer

Process - Effectiveness

1) Cycle Time - in total and by process step

2) Conversion & order close rates

3) Error or Defect Rates

Process - Efficiency

1) Sales cost per lead

2) Sales cost per order

3) Sales cost per dollar of revenue

4) Cost per sales call

See Post - Process Improvement In The Sales Process at

http://qualityg.blogspot.com/2007/01/process-improvement-in-sales-process.html