I can remember in 1972, the year before OPEC began to flex its muscles, prices were $1.28 a gallon.

October 1973 - A total ban on oil exports to the Unites States was imposed by the Arab oil-producing nations after the outbreak of the Arab-Israeli War. The ban was lifted March 16, 1974.

December 31, 1973 - President Nixon announced stand-by gasoline rationing in light of the Arab oil embargo. Gasoline stations had already begun voluntarily closing on Sundays.

Back in the 1973-1974 period and in 1979, folks waited for an hour or more on gasoline lines that at times stretched for miles, and people could only buy gas on alternate days, depending upon whether their license plate ended with an odd or even number. The federal government even printed gas-rationing coupons, although they were never used.

I can still remember all of the so-called efforts and story after story how we need to invent new ways for power so that we don’t have to rely on Foreign Oil. Heck, I even did a research paper on “Wind Power.”

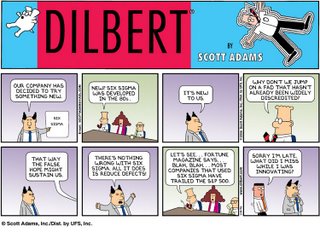

Six Sigma

I remember in the early 1990s the many articles written on the demise of TQM and the reasons for its failure.

Click on Reasons to Read

Reasons for TQM Failures

I could go through my boxes of old ASQ Magazines and find scores of articles about why it’s not a fad and why it’s failing. I even wrote reports on the subject and presented them to my Leaders.

Fast Forward to today and I can’t tell you how many articles are being written on how to fix Six Sigma from failing. Here is one recent example from the latest edition of Quality Digest.

qualitydigest/articles/Six Sigma Failure

What is interesting is this is nothing more than a maturity cycle. Consultants are trying to get their last drop of money from unsuspecting companies while they are also at work devising up the new quality buzz fad that is just around the corner. The most recent scam is to combine "Lean w/Six Sigma" and tell you now can get faster results. This is the same path that Michael Hammer took with "Reengineering" in the early 90s. He made a mint by saying this would get faster and more efficient results when TQM began to fade Quality Consultants needed another iron in the fire to keep their business going. Reengineering was really nothing new, in fact it was so fast it forgot (not really just felt they were not necessary) to include the employees. Leaders get excited when they hear faster and less costly and no problems from the employees.

Check this ad and site out from 7/31/06

Finally! A "Lean" Approach to Deploying Lean Six Sigma

Leap Technologies has pioneered a simpler, faster and more cost effective path to Lean Six Sigma results. By applying "Lean Thinking" to Lean Six Sigma we've elimiinated the “fat” from conventional deployment strategies that drives up costs and increases cycle times to results.

http://www.actionworkout.com/rlss_aleanapproach.asp

NOTE: The quality emphasis will move from Japan to China, South Korea & India for the remainder of the decade. It will be big, I mean big. The United States? - Status Quo, unless new leadership and management style is implemented in the major industries.

Let me give you a hint; it will be a combination of two types of efforts, and they both have the letter “Z” in their names. Please remember these methods are not new, but they will start creeping into consultants bag of magic tricks (Felix the Cat) by the end of the year. Where is the Professor and Rock Bottom when you need them!

Updated 2/4/07

I told you another Quality Method was on the heels of Six Sigma & Lean...

http://www.bmgi.com/upload/presscoverage/141.pdf

Additional information can be found at:

http://qualityg.blogspot.com/2006/11/misc-q-email-chute-on-quality-dilbert.html

updated 9/9/05

The following article was sent to me by Mike P.

This is exactly what I am talking about!

click to read---> Get a Lean Certification

qualityg says... Quality Evolution Gone Mad

updated 7/26/06

Please go to this site http://www.isixsigma.com/and look at the ads listed on the top and side. It was just a short time ago (less than a year) these companies did not have Lean or TWIZ in their advertising.

I wrote the following statement about five (5) years a ago.

Please! Please! Do not listen to Quality Consultants/Experts (Charlatans) who pontificate the so called difference between Six Sigma and TQM and all the other quality initiatives (BPI, TQL, Process Management, ISO 9000, MBNQA, Reengineering, TWIZ, Lean, or any combination of those mentioned, etc...). Six Sigma and the others will only add value if you use it as a means to get closer to your customers and your bottom line.

I will not support any improvement methodology that doesn’t take customer expectations and desires into account up front! That means before the "Bottom Line."

This has been the same message since 1980 when the Quality Movement was at its height in the United States. It's that simple!

Other related posts by qg:

http://qualityg.blogspot.com/2005/07/quality-tooltechnique-six-sigma.html

http://qualityg.blogspot.com/2005/04/quality-tooltechnique-six-sigma-been.html

qualityg says ... What did I learn? I learned that Oil Executives and Quality Consultants continue to gouge every dollar out their customers.

People just dust off your original training material, implement where it makes sense (design or improve product/service to customer), avoid past mistakes and execute.

Go to this site for 10 excellent reports on Six Sigma Quality http://users.bigpond.net.au/SixSigmaFallacies/

Scott Adams does it again: Click on Pic to Enlarge

3/1/07

There are blogs everywhere spouting the success of Lean Six Sigma. Unfortunatley if you question or provide input the Bloggers who support each others are the only ones to disagree or reply.

It is hard to admit the so-called Training that people have gotten to obtain SS Belts really mean nothing to those outside of their own environment. Using Martial Arts Belts to signify rank and smarts with Six Sigma was the first big mistake. If you want to be creative or come up with something "Really" new then don't use others Marketing Tools. Besides you do a disservice to the Martial Arts community. Who ever heard of getting a black belt in 2-3 weeks (don't argue this point, I have at least 10 sites that advertise this marketing crap).

I have 15 Quality Certfications (since 1980) including Six Sigma (took me much longer than 2-3 weeks), TQM, Baldridge, ISO, SPC, etc... There nice to have on a wall but mean nothing unless you prove and apply the principles. So, stop promoting the Tool/Technique and promote your application.

http://blogs.isixsigma.com/archive/six_sigma_and_standardization.html

http://blogs.isixsigma.com/archive/six_sigma_sucks.html#810

3/19/07

Six Sigma vs. TQM

A good debate between two Quality Experts (I'm with Mr. Harrington).

http://www.qualitydigest.com/nov06/articles/03_article.shtml

4 comments:

What about the Master Cylinder?

So true, Six Sigma is dying in my company after a 2 year run. The consultants got rich and I got a Green Belt. Now tell me qg what goes with green?

Jerry in PA.

J in PA,

How could I forget, best mention Poindexter and "Va VOOOOM."

Quality is an evolution, no more no less, take what what applies to your work and keep learning and applying, leave the BS on the next phase to Management.

In each quality effort there is something to learn, you just need to learn to wade through the crap.

qualityg,

Great post, the Six Sigma posts are right on target.

Clipped by a quality consultant

My company started six sigma a few years back and it failed, now they want Lean and I just heard about Lean Six Sigma!

I'm sending this post to our Q Department.

Felecia

Post a Comment